Engine Oil Centrifuges, Manufacturer, Exporter, Supplier and Dealer. Our setup is situated at Pune, Maharashtra, India

Salient Features :

- No replacement element

- No recurring cost

- Increased engine life

- Improved enigne operation

- Extended oil change period

- Finest filtration below 1µ

- Substantial savings on operating & maintenance expenses

Applications :

- Auxiliary Engines

- Main Propulsion Engines

- On Boards Cranes

- RTG Cranes

- Reach Stackers

- Stuffing Box Oil

- Gear Box Oil

- Hydraulic Oil

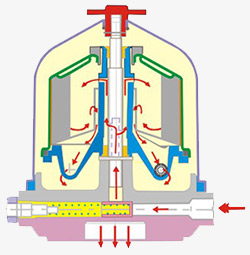

Working Principle

Centrifugal oil cleaner operates on reaction turbine principle. Oil enters centrifuge under pressure and flows into rotor thru hollow rotor shaft. The oil pressure and flow is converted in rotational energy as oil escapes through the rotor jets, producing speed upto 8000 rpm. The resultant centrifugal force removes dirt from the engine oil, depositing it on the inner wall of rotor in a dense cake form. Clean oil drains back to the engine oil by gravity.

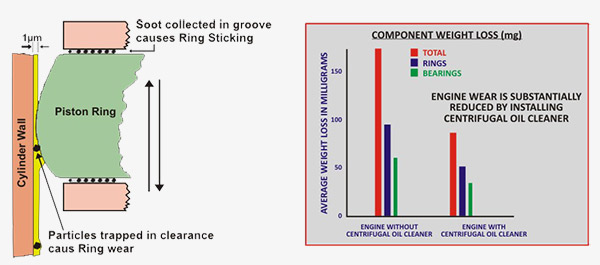

Why Centrifugal Oil Cleaner

Centrifugal oil cleaner operates on reaction turbine principle. Oil enters centrifuge under pressure and flows into rotor thru hollow rotor shaft. The oil pressure and flow is converted in rotational energy as oil escapes through the rotor jets, producing speed upto 8000 rpm. The resultant centrifugal force removes dirt from the engine oil, depositing it on the inner wall of rotor in a dense cake form. Clean oil drains back to the engine oil by gravity.

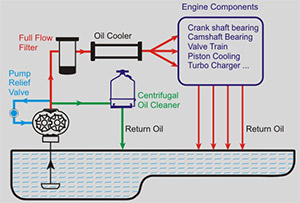

Schematic Diagram - Full Flow Filter & Centrifugal Oil Cleaner

Full flow filter carries entire oil flowing to various engine components, hence it has coarse filter element of 30 to 50 µ (to meet the flow requirement of engine components.) It removes large particles, however fine particles remain in the oil. Centrifugal oil cleaner is installed in bypass line. It is a multipass cleaning system, it processes small quantity of oil continuously & removes all the Particles present in the lube oil down to 1µ thereby achieving very high level of oil cleanliness.

Expenses Saved is Profit Earned

With Oilmax Centrifugal Oil Cleaner substantial savings can be achieved on three major engine operating expenses i.e. cost of Lube oil, Filters and Engine overhauling.

Save with OILmax

| Bypass Filter |

Save 100% |

| Full Flow Filter | Save 50 to 100% |

| Engine Oil | Save 50 to 100% |

| Overhauling | Save 50 to 100% |

Standalone System

Oilmax Centrifugal oil Cleaner is also available as Complete Standalone system, including Motor, Gear pump, Pressure gauge, Electrical switch gear etc., it is useful for cleaning onboard oils like Gear oil, Transmission oil, Hydraulic Oil, Fuel Oil, Stuffing Box Oil etc. It can also be used for cleaning engine lube oil of low rpm engines (with pressure upto 3 bar). The unit is mounted on wheels and can be easily moved.

Selection Chart - Engine Mounted Centrifuge

| Centrifuge Model | SCC 020 | SCC 025 | SCC 030 | SCC 050 | SCC 060 | SCC 0100 | SCC 200 | SCC 400 | SCC 600 |

| Nominal Flow Rate | 200 LPH | 250 LPH | 300 LPH | 500 LPH | 600 LPH | 700 LPH | 1200 LPH | 3000 LPH | 4000 LPH |

| Dirt Holding Capacity | 200 cc | 250 cc | 300 cc | 500 cc | 600 cc | 1000 cc | 2000 cc | 4000 cc | 6000 cc |

| Engine Oil Sump | 20 Ltrs. | 30 Ltrs. | 50 Ltrs. | 60 Ltrs. | 80 Ltrs. | 120 Ltrs. | 700 Ltrs. | 1500 Ltrs. | 3000 Ltrs. |

Selection Chart - Standalone System

| Oil Cleaning System Model | Centrifuge Model | Nominal Flow Rate | Dirt Holding Capacity | Dimension (W x D x H) inch |

| OCS 500 | SCC 075 | 500 LPH | 500 cc | 24 x 14 x 32 |

| OCS 750 | SCC 100 | 750 LPH | 1000 cc | 24 x 14 x 34 |

| OCS 1500 | SCC 200 | 1500 LPH | 2000 cc | 24 x 16 x 39 |

| OCS 4000 | SCC 600 | 6000 LPH | 6000 cc | 30 x 18 x 46 |

Installation