Salient Features :

- No Filter Element

- No Replacement Cost

- Improved Product Finish

- Reduced Oil Consumption

- Extended Oil Change Period

- Reduced Machine Downtime

- Reduced Pollution & Environmental Impact

- Reduced Storage & Disposal Cost of Waste Oil

Save by Extending Oil / Coolant Life, Tool Life and Machine Life

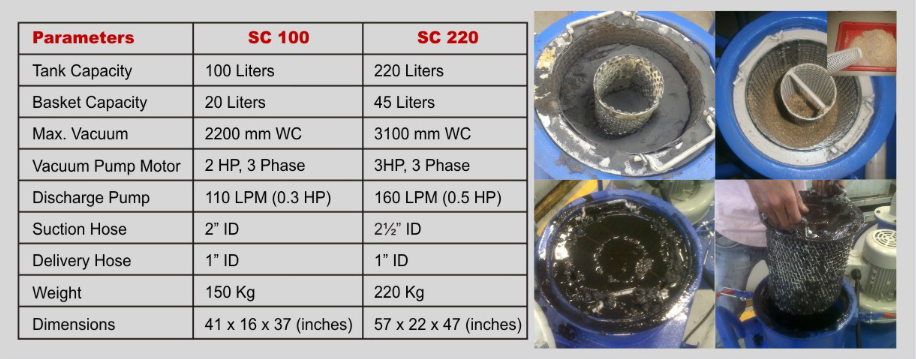

Sump Cleaner removes very fine dirt from Oil / Coolant upto 10µ & below by Vacuum created in the tank. There are no consumables hence no recurring cost. Collected dirt can be easily cleaned & the unit put back to use again

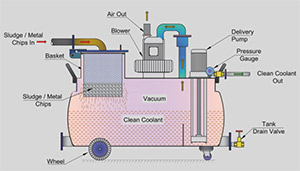

Working Principle

Oilmax Coolant / Sump Cleaner removes sludge, metal chips & swarf from Coolant / Oil tanks & filters it via reusable steel mesh filter. The System Works on the Principle of Vacuum Suction. A powerful vacuum blower creates vacuum in the tank of the unit, which sucks in coolant, metal chips Swarf etc, passing it thru mesh basket. Contamination gets collected in the basket & clean coolant flows through to the tank of the unit. A centrifugal delivery pump delivers back the clean coolant.

Applications :

- Soluble Cutting Oil

- Neat Cutting Oil

- Water Emulsion

- Quenching Oil

- CNC Machines

- Storage Tanks

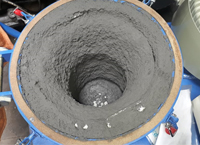

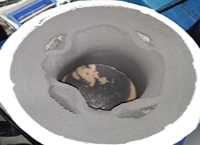

Installations

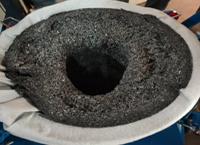

Sludge Collected